Delivery and Packaging

DFS Food's Logistics and Delivery Procedures

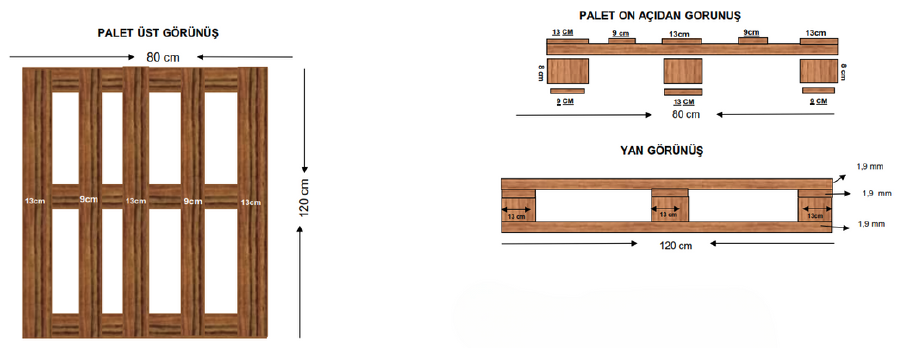

Master data management for Packaging and Palletizing is of great importance at various stages of service and product processes. Issues such as pallet height and weight calculation, ordering processes and storage planning are managed in line with this data.

In general, the packaging process should take into account ease of stacking, handling and product identification. At the same time, the use of excess packaging should be minimized, it should be collapsible and should not contain more than one type of product. This allows for more efficient waste management and eliminates the need for additional sorting.

In addition, the stretch film used around the pallets should not be black.

Used to preserve the freshness and nutritional value of products.

Extends shelf life by minimizing contact with oxygen.

Damage that may occur during transportation is prevented by using sealed and durable packaging materials.

Packaging that provides multi-layer protection is preferred for the safe transportation of products.

They are designed to be easily stackable and not damaged during transportation.

Sustainable packaging is ensured by using recyclable and environmentally friendly materials.

Pallet and parcel labels clearly contain product information.

Labels must be resistant to water, heat and cold and must not deteriorate during transportation.

For each product on the pallet, the product name, batch number, production date and expiration date must be included.

As DFS Gıda, we continue to offer market-specific, innovative and reliable solutions with our customer-oriented approach.

We offer customized product development and production services so that our customers can sell under their own brands. For example, labeling options can be tailored to customer requirements. Furthermore, we offer flexible production and packaging options such as vacuum packaging, industrial bulk packs and retail packaging.

All shipments should be made with 80×120 cm EUR pallets.

Road transportation (TIR shipments) is preferred for Europe.

Maritime container transportation is used for overseas countries.

Air cargo options are also considered in special cases.

The 80×120 cm Euro Pallet capacity for Reefer TIR is calculated to be approximately 33 pallets. This is the capacity achieved when the pallets are optimally stacked.

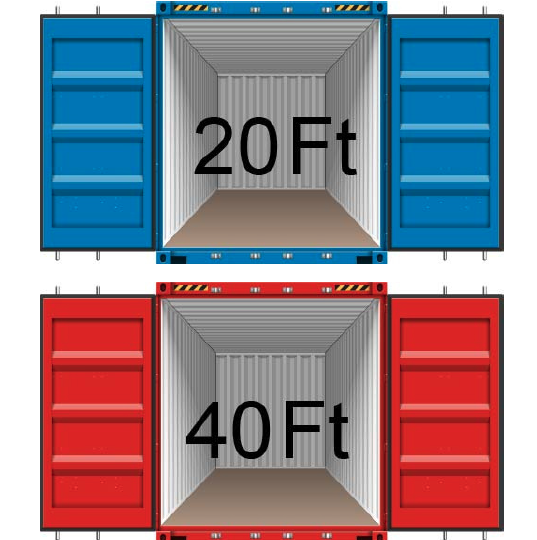

Euro Pallet Capacity for 20ft and 40ft TIR:

20ft TIR: 10-11 pallets (with optimal placement)

40ft TIR: 22-23 pallets (with optimal placement)

These values are calculated for optimal stacking of pallets. They may vary depending on the loading arrangement and the efficient use of the space used.